ID3. Heating and Cooling systems.

While we wait for the ID3 delivery which should be just around the corner, let's have an in-depth look at the air-conditioning and cooling system of the VW ID3.

The ID3 is build on top of the MEB platform which is a new ground up platform that is dedicated for EVs. This allows VW to do a few things differently when it comes to cooling and heating.

What we will cover in this article:

- Interior HVAC (Heating, Ventilation and Air Conditioning)

- HVAC system internals

- HVAC electrical system

- Why CO2 refrigerant makes the ID3 a better EV compared to the rest

Interior HVAC (Heating, Ventilation and Air Conditioning)

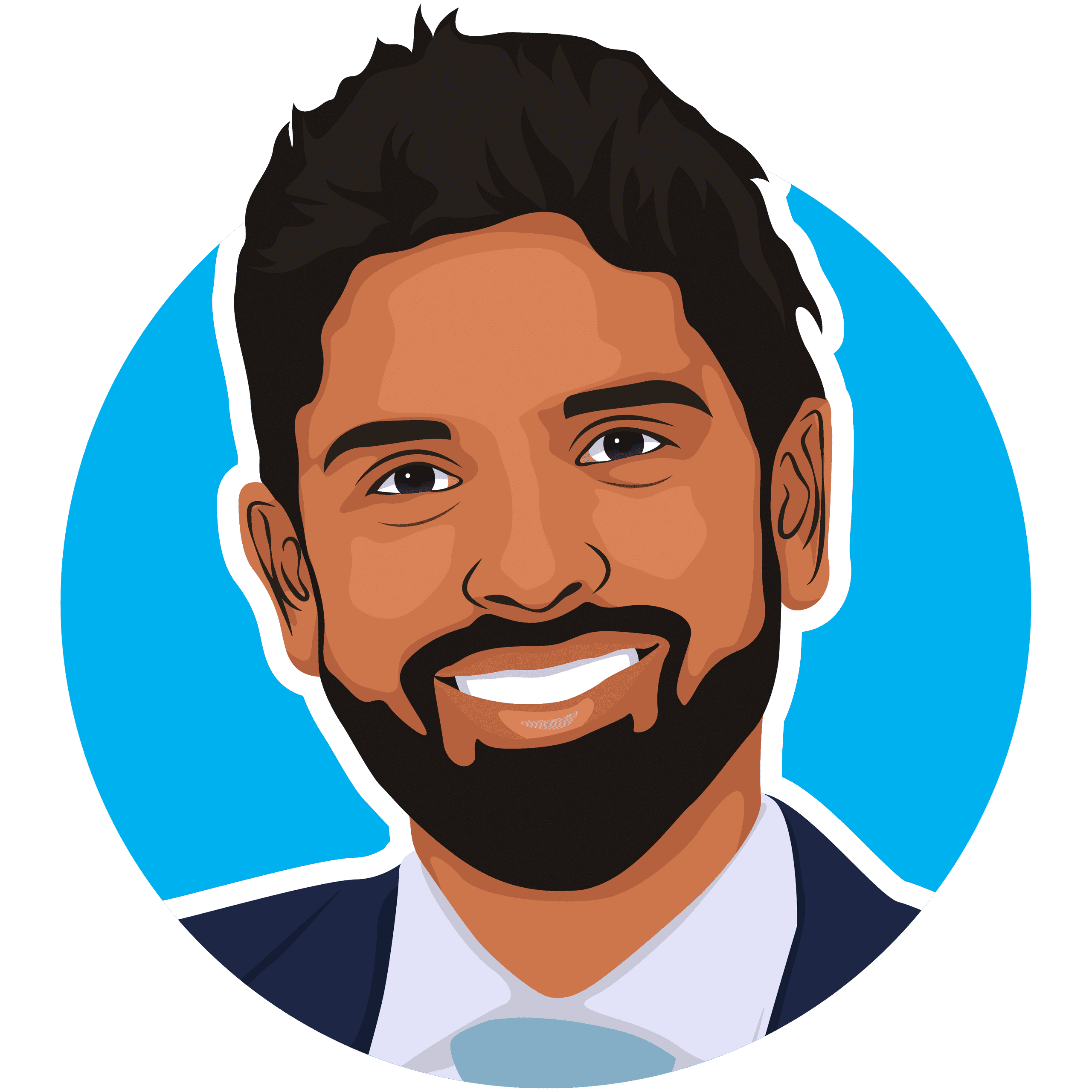

Let's start of with the interior, we have 11 air conditioning vents:

- 4 vents directed at the two front passengers

- 2 foot-well vents

- 2 door and window vents

- 1 windshield vent

- 2 rear passenger foot-well vents

| Item | Description | Part # / Notes |

|---|---|---|

| 1,2,3 | Passenger air vents | Available in unspecified colors |

| 5 | Air vent for window | Available with chrome detail |

| 6 | Air vent for door window | 1EA 816 701 A |

| 7,8 | Front passenger foot air vent | |

| 13, 14 | Rear passenger foot air vent | |

| 26,2 | Intake manifold |

As you can see in the above diagram there are no vents that can be adjusted for the rear passengers. The only vents are for the rear passenger footwell.

One last thing of interest is that the air vents do have an option for a chrome frame. However it's not clear which versions of the ID3 support chrome air vents.

HVAC system internals

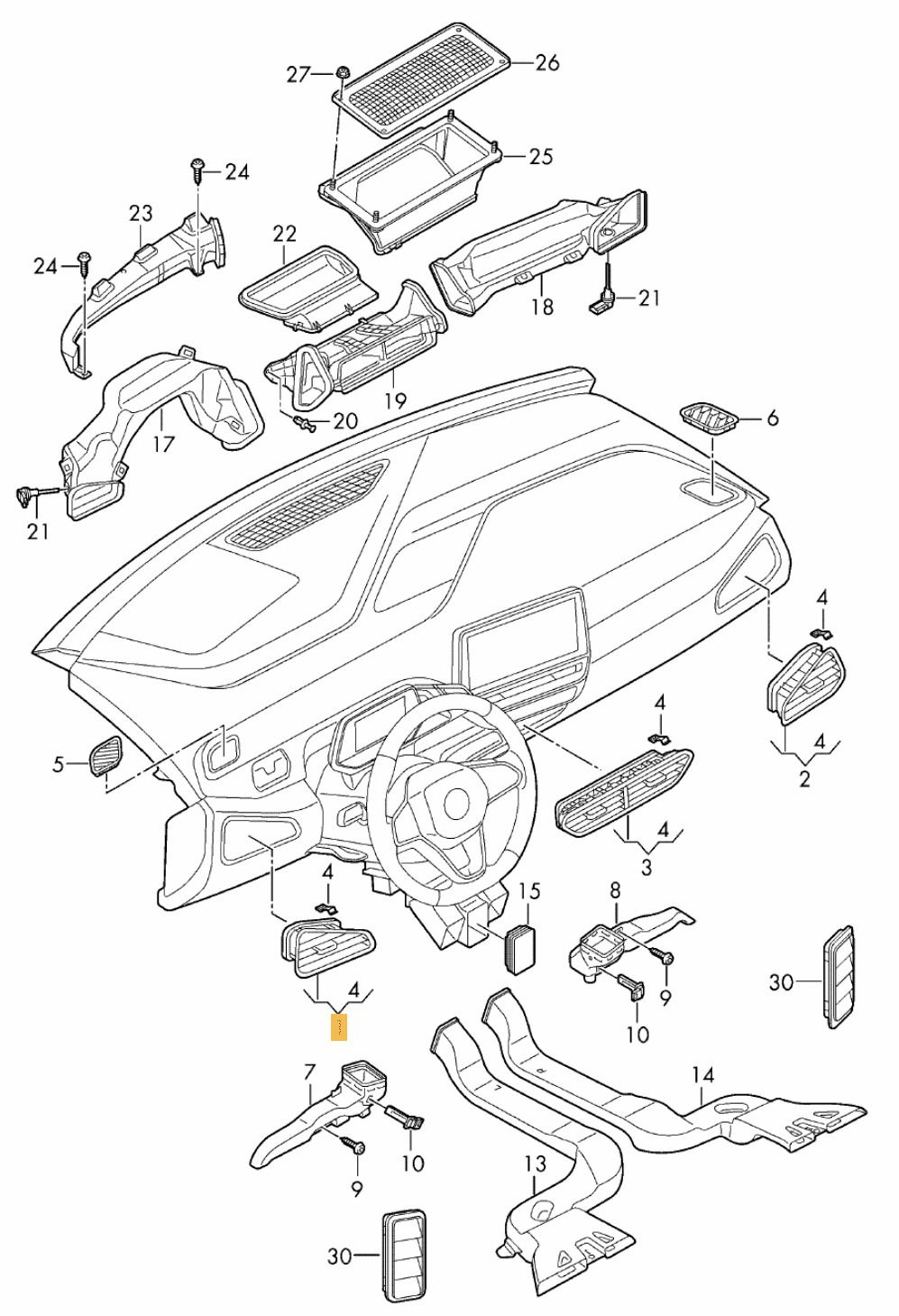

Lets start with one of the key components of the ID3 HVAC system, the compressor.

The compressor is the power unit of the HVAC system that puts the refrigerant under high pressure before it pumps it into the condenser, where it changes from a gas to a liquid. By pumping the refrigerant from one state to another it allows the system to pump heat from one side to another. The fundamental function of the ID3 compressor is the same as in the HVAC system of your heat-pump water heater or home ac system. A quick intro to the operating principle of heat pumps can be found here

| Item | Description | Part # / Notes | Part price in NOK |

|---|---|---|---|

| 1 | Compressor | 1EA 816 797 E | 13, 087 NOK |

| 3 | Bracket | 1EA 816 579 B | 135 NOK |

| 5 | Isolator | 1EA 816 579 B | 358 NOK |

| 7 | Bracket for invertor |

The above shows the compressor housing for the ID3. The compressor that is used supports both the air con heating/cooling loop and the battery heating/cooling loop. As we dig further into the design of the ID3 HVAC system you will see that the battery conditioning system is efficiently tied to the cabin conditioning system allowing for heat to be moved from one system to another.

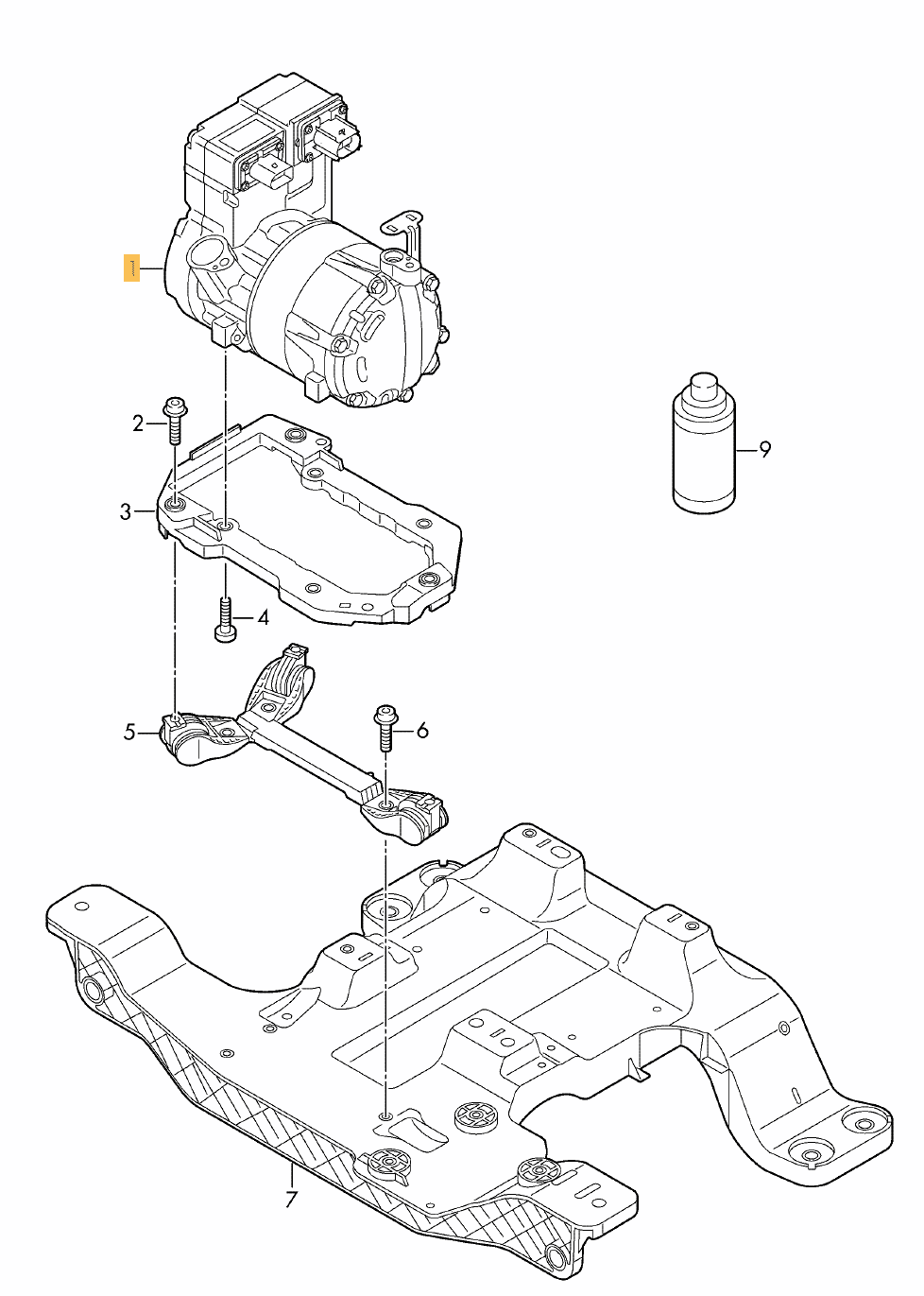

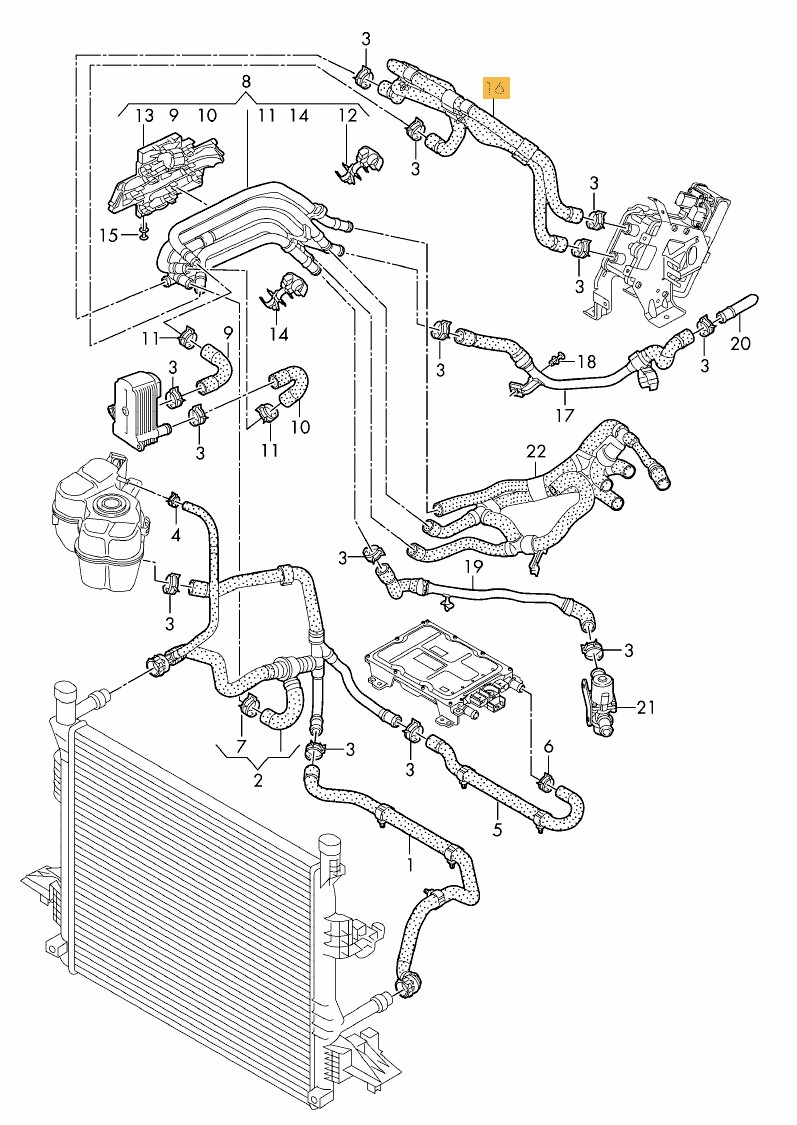

The diagram below shows how the compressor is connected to the rest of the hvac system.

| Item | Description | Part # / Notes | Part price in NOK |

|---|---|---|---|

| 1 | Condenser with dryer | 1EA 816 411 A | 3,292 NOK |

| 2 | Refrigerant Dryer | ||

| 10 | Refigerant Line | 1EA 816 743 A | 2,358 NOK |

| 11 | Pressure and temperature sensors | 4M0 959 603 C | 1,192 NOK |

| 18 | Refregerant line | 1EA 816 741 E | 2,531 NOK |

| 40 | Heater Core | 1EA 816 111 B | 6,983 NOK |

| 44 | Bracket for heat exchanger | 1EA 816 087 A | 90 NOK |

As you can see above the compressor is connected to a traditional looking system. Note that #40 is the heat exchanger.

The ID3 has two independent cooling loops for the battery heating and cabin heating system. The main advantage here is that this configuration allows the heat pump to cool the battery while at the same time heating the cabin ( or vice versa).

The heat exchanger allows for heat energy to be efficiently moved from one system to the other. This means that if the cabin is cold but the battery until is warm, the ID3 can efficiently move the heat from the battery cooling loop to the cabin loop. The heat exchanger (#40 above) has the 4 connectors for the 2 different loops

While the heat pump is awesome there is still a HV resistive heater. the ID3 has a PTC (Positive Temperature Coefficient) Heater which generates heat using electricity from the HV battery pack. You can see this in the top right of the cooling loop diagram below. This diagram shows how the PTC heater is used to heat the liquid used to heat/cool the battery. This is how the ID3 is able to heat and cool the battery in order to maximize the performance of the battery pack.

Why CO2 refrigerant makes the ID3 a better EV compared to the rest.

The ID3 uses CO2 as a refrigerant. CO2 (aka r744) is a pretty awesome refrigerant that is ideal for electric cars such as the ID3. The benifits of CO2/r744 is widely known and include:

- CO2/r744 is a Global Warming Potential of just 1. This is much lower than almost every other type of refrigerant used or proposed.

- If all new cars were to just switch their HVAC system to CO2/r744, we could reduce global CO2 emmistions by 10%!

But there is a more important reason why CO2 is the best refrigerant for EVs.

Heat pumps are important for EVs. Without an internal combustion engine generating heat, the only souce of energy availabe to generate heat is the HV battery. And the best and most efficient way to generate heat is via a heat pump, fact.

Now we all agree that heat pumps are crucial for an EV, but in the case of R1234yf heat pumps this is only possible at ambient temperatures no lower than -5 °C. If the temperature falls below this level, additional electric heating is needed. By contrast, R744 heat pumps supply more heat at temperatures below -5 °C and have no leaks of the kind that develop in other systems as a result of negative pressure conditions. This makes R744 the preferred solution.

So if CO2 is the best refrigenant for an EV, why do some companies still use R1234yf as a refrigerant? Well the main reasons are:

- They are building EVs on an ICE platform. For an ICE(internal combustion engine) car the ability to capture heat efficiently is just not required. The engine provides plenty of heat so they don't need to be efficient at capturing it.

- You cant just convert existing R1234yf systems to CO2/r744

- CO2/r744 systems run an considerably higher pressure which makes them more expensive to engineer.

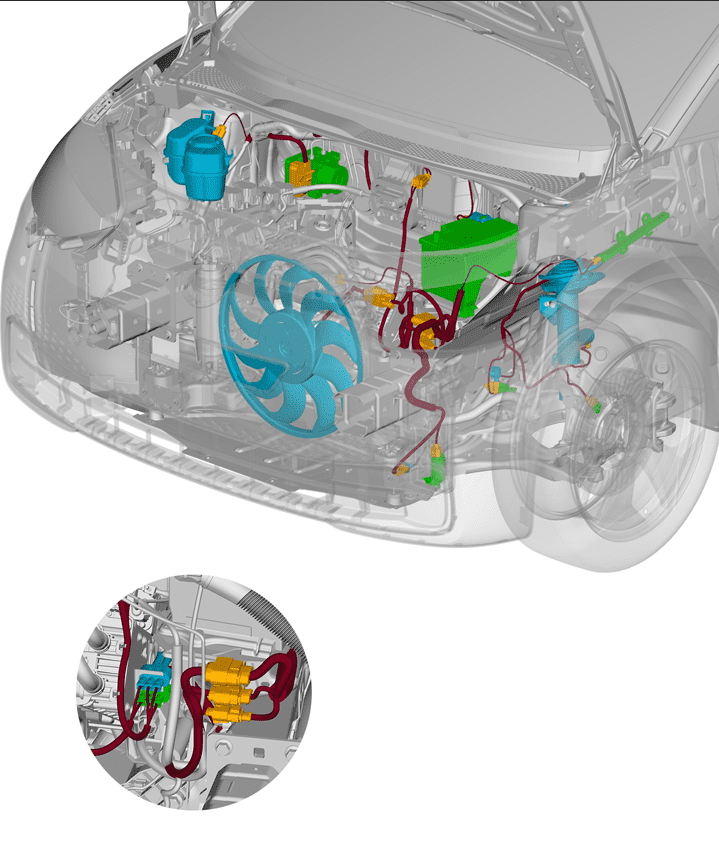

HVAC system wiring

Let us know what you think in the comments below!